Dust from masonry work leads to OSHA complaint

Letters describe response, including air quality test, window taping, and shift in work schedule

June 3, 2015

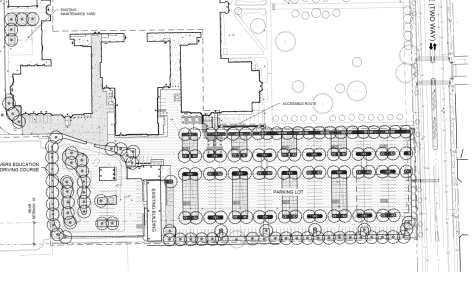

Lane’s timeless façade has seen the addition of tarps and scaffolding this past semester as major construction work is being completed to ensure that the structure of the school stays sound for years to come. Some of these major changes have included grinding in between the mortar of the bricks and will expand to even larger projects such as replacing the roof and all of the windows over a process of two years.

The mortar work caused dust and loud noise to come into some classrooms, even leaving visible traces on desks and keyboards according to Autumn Schroeder, Div. 674.

“One morning in my dual period class, we had to sit in an unfinished computer room instead of doing a lab because there was so much dust. If you moved a book there was visible dust on the table where the book had been and the dust wasn’t,” Schroeder said.

A question about the safety of the dust coming into the classrooms led to an official complaint being filed with OSHA, the Occupational Safety and Health Administration, according to a letter from OSHA Division Manager Ben Noven dated April 24. The letter cited air quality, specifically the dust and mortar particles, as the alleged hazards to students and staff members.

Noven’s letter instructed CPS and Lane to take “corrective action” by May 6, and if not the Illinois Department of Labor (IDOL) would conduct an inspection to analyze the possible hazard presented by the construction.

The letter written back to Noven from CPS Deputy Chief Facilities Officer Mary De Runtz says that the complaint was addressed in many ways.

First, the CPS Department of Facilities hired a consultant group to administer an Indoor Air Quality survey on April 24.

The results provided by the GSG consultant group showed that the percentage of airborne particulates were an average of .0236 milligrams per cubic meter based on five measurements taken in room 260. According to GSG, this number is well below the Illinois Department of Public Health guideline of .150 mg/m^3.

The dust concerns were also brought to the attention of the General Contractor of Tyler Lane Construction, who covered and taped all windows and air conditioning units, according to De Runtz’s letter, which is dated May 10. Tyler Lane also moved the masonry work to second shift, which follows the end of the school day.

Before these changes were made, Autumn Bland, Div. 656, said she experienced two asthma attacks in the span of three days, on April 27 and April 29, when she said that dust entered through the windows that were closed but somehow managed to move past the pane.

“You could see dust coming into the physics room,” Bland said. “It was very visible and dense.”

As soon as the dust was recognized as a problem, the class was promptly moved into the hallway, according to Bland.

Classrooms were consolidated early in the school year in order to make six rooms available for classes displaced by construction, Dr. Dignam said.

“We made sure we set aside rooms in case this ever became a problem so that the teachers would be able to move their class,” Assistant Principal Mr. Ara said.

The final letter written by Noven to Barbara Byrd-Bennett dated May 12 stated that because of these preventative measures the complaint was officially closed unless appealed by the complainant (the person from the which the complaint originated).

Construction to finish in 2017

The construction plan, which was originally limited to window replacement, expanded to what it is today after Assistant Principals Mr. Ara and Ms. Gonzalez took video of water damage to show CPS. The necessity of the renovations, which was supported by Mayor Rahm Emanuel and the Board of Education, is evident when it rains.

When it rains it looks like someone is pouring a garden hose, but it’s coming inside the building,” said Dignam.

According to Dr. Dignam, a temporary roof will be installed at the beginning of November, and the permanent roof and a remodeling of the attic will be finished by the following March.

The large chunks of brick missing from areas such as the southwest corner of the lunchroom are for structural engineers to test the building.

Along with these structural changes, the interior of Lane is getting a facelift with remodeled chemistry classrooms and a new coat of paint in every room. Dignam’s painting ideas would make building easier to navigate.

“Each major entrance of the building will have a color code,” he said.

The next two years at Lane will be a time of constant renovations and the occasional plan B, but at the end – Feb. 2017 according to Dignam – the 100-year-old building will be able to continue to be a well functioning school.